Data Acquisition, in the broadest sense, is a process of collecting information on some real-world, physical system, and using this to analyze the system in question. In most cases, the system being measured is an industrial process or scientific experiment, and nowadays the data collected is almost always passed to some form of computer.

In recent years, the technology used to collect, process, and analyze such data is available off-the-shelf. In comparison to earlier systems, which were normally bespoke designs specific to a particular field or process, the use of off-the-shelf components means that they can be replaced easily and cheaply.

There are many factors to consider when designing and implementing a data acquisition system. First and foremost, the types of sensors used to collect data must be carefully though out. Secondly, the signal output by these sensors needs to processed into a form which is acceptable for a digital computer. Lastly, the software running on the computer being used to collect and analyze data must fit the purpose at hand.

For most engineers and scientists today, the standard choice of hardware is a PCI-based system. These systems use a standard connection between signal-collecting hardware and the hardware of the computer used to analyze this data. Though originally designed for the PC, in recent years PCI cards are available that will also work with Mac and other forms of computer system.

Today, I will give a quick introduction to the design and implementation of such systems, broken into the three main factors that must be thought about – the sensors used, the choice of signal processing controller, and the hardware and software required to work with the data collected.

Sensors

When designing and implementing any PCI data acquisition system, the first thing that must be considered is the type of sensors required. Whilst there are now sensors available for almost any kind of physical variable you wish to measure, it is worth noting that any sensor is likely to effect the operation of the system you are measuring, and it is therefore wise to use the minimum number of sensors required for your purposes.

In practice, this means carefully thinking through exactly the data you need to collect from the system you are interested in, and focusing on that type of data. Typically, one reading can act as a proxy for the total operation of the system – for instance, one of the most common variables measured by PCI data acquisition systems is temperature, which in many cases is used to indicate the smooth operation of industrial hardware.

Other examples of common phenomenon that measured by PCI data acquisition systems are light intensity, gas pressure, fluid flow, and force.

Signal Processing

Typically, PCI data acquisition systems use dedicated hardware to pass signals from sensors to the computer systems that will collect and analyze the data. Converting a messy, sometimes noisy, signal from a physical system into a format that can be used and manipulated on a computer can be a tricky business.

One of the first obstacles to be overcome in this regard is signal strength. As outlined above, typically sensors are designed to take the smallest amount of energy possible from the system they are being used to measure. In practice, this also means that the signal they output is of a vey low intensity, and must to amplified to be of any use.

It is therefore critical to use an amplifier that is able to amplify the signal cleanly. A noisy amplifier will ultimately warp and color the data collected, which in some cases can render it useless.

Another thing to think about when designing a PCI data acquisition system is the type of signal that you will use to pass data between the various parts of your system. Most sensors will output a single ended analog signal. Whilst this type of signal is good at capturing the raw state of the system being measured, it is also very susceptible to noise and distortion. A common fix for this problem is to convert the signal coming from the sensors into a differential signal, which is much more stable and easier to work with.

PCI Data Acquisition And Signal Processing Controllers

Once the signal has been amplified and cleaned up, it must be fed into a computerized system for collection and analysis. Nowadays, most data acquisition systems use standard PC hardware, meaning that if components of the system fail, they can be easily replaced with off-the-shelf items.

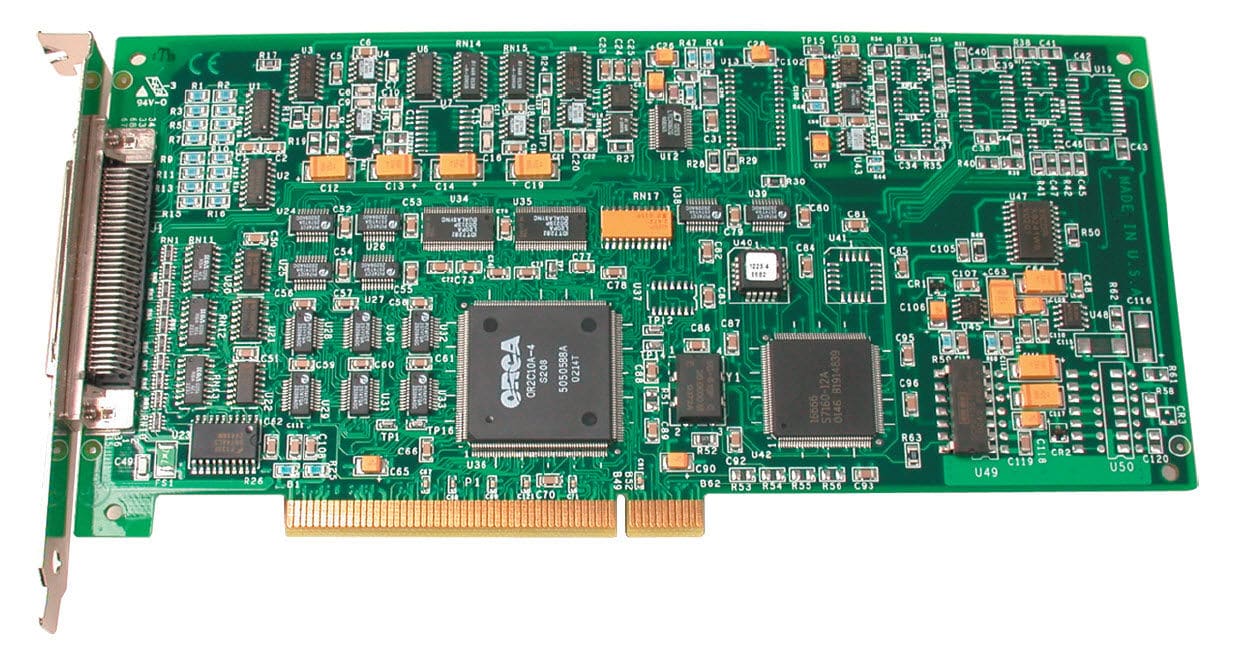

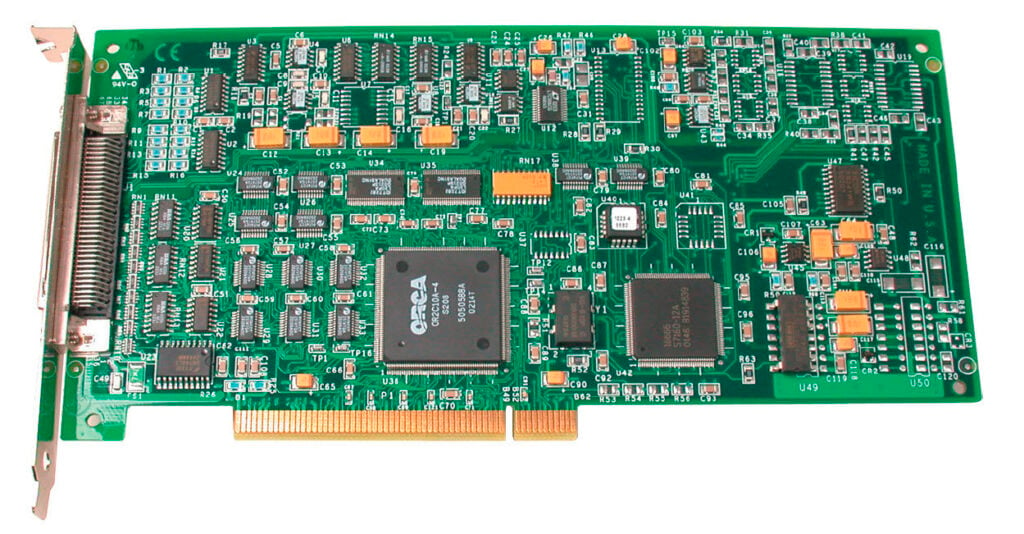

The most common format for getting an incoming signal into a computer nowadays is the use of PCI cards and other hardware. Though originally designed for PC, PCI cards compatible with many other systems are now available.

These external PCI cards are a solution to a common problem – that with complex data acquisition systems measuring many variables, the number of PCI inputs on a typical motherboard is too few. To work around this problem, an external card is used to combine multiple signals into a single input.

DAQ cards often contain multiple components that are able to perform signal processing before passing the signal to the software. In the most advanced cards, these functions are accessible via a bus by a micro-controller, though some cheaper systems used hard wired logic. For both types of card, proprietary device drivers are often needed.

These signal processing controllers are increasingly able to perform quite complex processing on incoming signals. For complex PCI data acquisition systems, this is invaluable for several reasons. First and foremost, it shifts the burden of signal processing away from the CPU, which in large complex systems can become choked by an overload of data.

The final stage in processing the signal is to pass it to software. Nowadays, a vast variety of different software solutions are available for use with PCI data acquisition system, and the choice of which to use depends on the type of data being collected and how it needs to be processed. Typically, however, such systems are based on commonly understood programming languages such as C++ or MATLAB, providing a large scope for customization.

Which to Choose DAQ Cards or DAQifi Products?

DAQ cards typically output data using a dedicated hard link, and in years past this often meant having a separate PC workstation for every data acquisition process. Not only did this mean extra expense in terms of hardware, it often meant that bringing data from several processes together was a manual, painful business. DAQifi cards send the collected data over a WiFi network – either an existing one, or one generated by the device itself – to custom software.

What this means in practice is that a single PC, tablet, or even smart phone can be used to aggregate all the data being collected, bringing it all together for easy analysis and manipulation. This also means that the computer being used to collect and manipulate data does not need any additional hardware to be used for this purpose.

In addition, DAQifi devices represent better value than many DAQ card solutions. This is because DAQ cards are often made to be used to collect one type of data only, and in many cases this means that a bank of cards must be used in order to collect even quite basic data. The flexibility of DAQifi devices makes them cheaper to implement in many situations.

This is especially true in situations where portability is paramount. The fact that DAQifi devices run on their own power makes them ideal for situations where having a dedicated PC workstation is simply impossible. This is the case in many industrial processes, where the environment is not conducive to the health of computer hardware, and also in situations where the system under study is inherently mobile, such as in automotive engineering.

Lastly, the user interface which comes as standard on DAQifi devices means that using them is incredibly simple in comparison to many DAQ card solutions. Often, even in high-end scientific applications, all that is needed from a data acquisition system is for it to feed data to a centralized device, in a format which is easy to work with, for later analysis.

This is exactly what DAQifi devices achieve, and it is therefore not surprising that they are eclipsing DAQ card solutions in many situations.

Read more about this in our DAQ vs DAQifi post.